- Homepage

- News and Features

- How automation is transforming greenkeeping – without replacing greenkeepers

How automation is transforming greenkeeping – without replacing greenkeepers

Technology influences our lives in new ways with every passing day. And that very much includes the world of greenkeeping, where exciting possibilities are waiting to be applied to clubs like yours.

It would be easy, but wholly mistaken, to view automation in agronomy as a means to reduce the need for greenkeepers. With all these robotic lawnmowers, who needs humans anymore? Allow us to put the record straigh immediately.

"Automation allows the machines to take care of the areas that would consume quite a lot of time for a number of staff to maintain," said Andrew Lees from Husqvarna, the market leaders in the sector of autonomous greenkeeping equipment. "But this isn't about replacing staff, rather freeing them up to focus on other tasks. The less time spent on those laborious areas means more time dedicated to taking care of the greens, bunkers and tees. Greenkeepers will tell you it's the ability to spend more time on those aspects that makes the biggest difference to being able to produce the best conditions and therefore the best playing experience."

"The feedback at our club has been really positive. Many of our staff are now able to dedicate more time to take on and complete jobs we didn't previously have the capacity to do as often as we'd like."

Warren Bevan, course manager at Carus Green

We wanted to speak to greenkeeping teams who are already employing autonomous equipment to find out what their experiences have been and exactly how they are harnessing the technology. We are, of course, still at a relatively early stage of automation in agronomy. The picture is changin almost by the day. Can your course really afford not to be moving in this direction?

CASE STUDY: Carus Green’s journey to automation

Course Manager Warren Bevan uses autonomous mowers at his Cumbrian club. The feedback from members and staff has been overwhelmingly positive

CARUS Green embarked on a journey to full automation in 2023 after being won over by the demonstration of autonomous machinery on its driving range. The 18-hole course, located on the outskirts of the Lake District, now operates a 10-strong fleet of automated machines, covering practically every blade of grass on the course’s fairways and rough. But what do the members make of it? Course Manager Warren Bevan, who is one of four humans on the otherwise robotic greenkeeping team, explains how they work together.

Why did you decide to adopt autonomous mowers at Carus Green?

We’ve always been progressive and forward thinking in our approach to new ideas and technology and, after a short demonstration, it became apparent that robotics was absolutely the path we needed to explore.

How long did it take you to get up to a fleet of 10?

The time period from implementing the first machines to rolling a full fleet of mowers out across our whole course was approximately six months – a quick transition but we haven’t looked back. It took some time to get all the necessary infrastructure and electrics installed, but nine months later we’re enjoying the benefits of being fully automated on all fairways, rough and approaches.

What have members had to say about it?

The feedback we received from the members was overwhelmingly positive, with many noting the improvements in the quality of the finish, and in particular the edge of the fairways which are now immaculately maintained due to the mower’s GPS navigation system. Members also commented on the reduction in noise pollution as well as the absence of tyre marks, which our former ride-on mowers sometimes caused during wet conditions.

And how about the greenkeeping team?

The feedback from our greenkeeping team has also been really positive, with many of our staff now able to dedicate more time to take on and complete jobs we didn’t previously have the capacity to do as often as we’d like, such as edging bunkers, which has now increased from once every two weeks to once a week.

How has automation helped overcome industry challenges?

There are two main issues that robotics have helped us to overcome. The industry is currently navigating changes to the climate, with more frequent wet days making maintaining the quality of the cut typically difficult, however, robotics really help overcome these challenges, as they can cut in any condition, whereas a conventional ride-on mower simply can’t. Last year, we were able to mow the course throughout March and April, which we haven’t been able to do in previous years.

The other challenge robotics has helped us to overcome is the labour shortage. The industry is experiencing a huge drop-off in the number of greenkeepers, and robotics has not only helped plug this gap but has also freed up staff to do jobs that they previously didn’t have time to do.

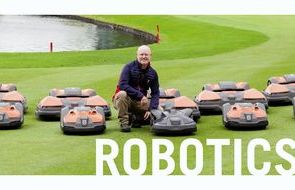

Warren explains how the machines are deployed at Carus Green

Four of our five Husqvarna CEORAs are cutting the fairways at a 10 millimetre cutting height. Those machines cut overnight, every night while the course is closed so as to not interrupt the golfers. The machines will then recharge before automatically changing their cutting height and commencing the rough cutting during the day at 60mm. Four other machines are cutting the carries from tee to fairway around the clock on a 24-hour cycle, and the other CEORA maintains our driving range split into different zones and can cut the full range over the space of 48 hours. This has eliminated significant hours of labour a week for our team, who can now focus on other tasks in that time. The last machine cuts an area just in front of the clubhouse.

CASE STUDY: Full automation at Cranham

With its fleet of robotic mowers, this parkland Essex course has embraced full automation. Does it provide a glimpse into the future?

Cranham is reputed to be the first 18-hole golf course in the UK to utilise autonomous mowing across all of its fairways and first-cut rough – and the Essex venue is now reaping the benefits.

It was back in May 2023 that Cranham, a public course, adopted the technology to maintain the vast bulk of its 350,000m2, par-67 layout. With its eye-catching, island-green closing hole, Cranham has developed a glowing reputation for the quality of its course, something managing director Barney Cameron says is directly related to the club’s high-tech turfcare.

“We’re constantly investing into grounds maintenance,” he said. “Ultimately, the condition of the course is what’s going to keep players happy and keep them coming back over the long term. As a public course, there is no resting on our laurels. We’re more vulnerable to rising costs than a member-only golf club that tends to have both fixed and diversified revenue streams. “We quickly realised that we needed to find ways to minimise future cost increases without sacrificing our reputation for the quality of the course.”

Barney found his greenkeeping team were too stretched to be able to deliver the standards they were capable of, and he needed a solution.

“Our guys are excellent, a real asset to the business, but we realised that we were not able to utilise their expertise to the fullest,” he explained “By the time they’d finished mowing the fairways and rough, there was limited time left for managing bunkers, repairing divots, green management and improving drainage. It was like owning a sports car but mostly using it for the run to the supermarket rather than driving it at its fullest potential on a racetrack.”

Cranham turned to automation as a means to alleviating the workload on the greenkeeping team, affording them time to tend to the more skilled work and leaving machines to do the lion’s share of the cutting.

The club undertook a two-week trial with two ECHO robots, which mowed the fairways 24 hours a day. The impact on the course, and on the team, was significant.

“We just couldn’t believe the result,” said Barney. “We walked the course after only a couple of days and the finish was incredible. Given the huge area being cut, I was expecting to find at least a few areas missed or an uneven cut on slopes. I really thought we would need to tune the robot’s performance over a number of weeks, but it was near-perfect from the start.”

It was not just the staff who were impressed, as players also noticed a difference in the playing conditions, which showed a marked improvement thanks to both the mowers and the ability of the greenkeeping team to focus on more targeted work.

“What really took me by surprise was the secondary benefit that the robots have given us,” Barney explained. “Last year, for the first time in a long time, we had the capacity to really focus on drainage, bunker maintenance and proper management of our hedgerows. Customers have noticed the difference and commented on the improvement. We used to have to sub-contract out this kind of work, but now we have the time to do it ourselves and, quite frankly, we do a better job of it. I feel that our greenkeepers are even more engaged these days too. They’ve finally got the time to focus on what they’re best at and I can’t help but feel that they’re going home a little more satisfied with their work than they were before.”

What to read next

How automation is transforming greenkeeping – without replacing greenkeepers

Author