- Homepage

- News and Features

- Kaizen for Greenkeepers: Japanese Business in Italy

Kaizen for Greenkeepers: Japanese Business in Italy

What greenkeepers can learn from Japanese business principles making their home in northern Italy.

Close to Reggiolo, the hometown of Carlo Ancelotti, is the Kubota Gianni Ferrari factory, where a commune of Japanese engineers are bringing an Asian business philosophy to this corner of northern Italy.

Kaizen, meaning ‘change for the better’, has long been a foundation of Japanese business practices. A constant quest for improvement, tiny operational changes and the empowerment of staff make small differences that over time add up to major gains.

We all face challenges, but could tiny changes over time eventually make a huge difference to your business, whether it be a factory in Italy creating machinery, or maintaining a parkland golf course in the Midlands?

Junsei Komiyama is president and managing director of Kubota Gianni Ferrari. Having previously worked to implement Kaizen principles in Germany, Netherlands, France, Sweden and Denmark on behalf of Kubota, he said: “People like to improve and they want to change. If people see an improvement every day, they enjoy what they are doing.”

So where do you begin?

Key to starting on the journey is shedding your own ego. Constantly looking for ways to improve means you acknowledge the way you do things may not be the best. Instead, let go of assumptions and be open to new ideas, with the mutual understanding that this is a two-way process and others must understand your expertise is just as valuable.

Then, once the best approach has been decided upon, it’s important the process is shared and adopted by the entire team. A multi-skilled workforce is ideal as it prevents activities ceasing to a halt if the only person who can do the job is ill or on holiday.

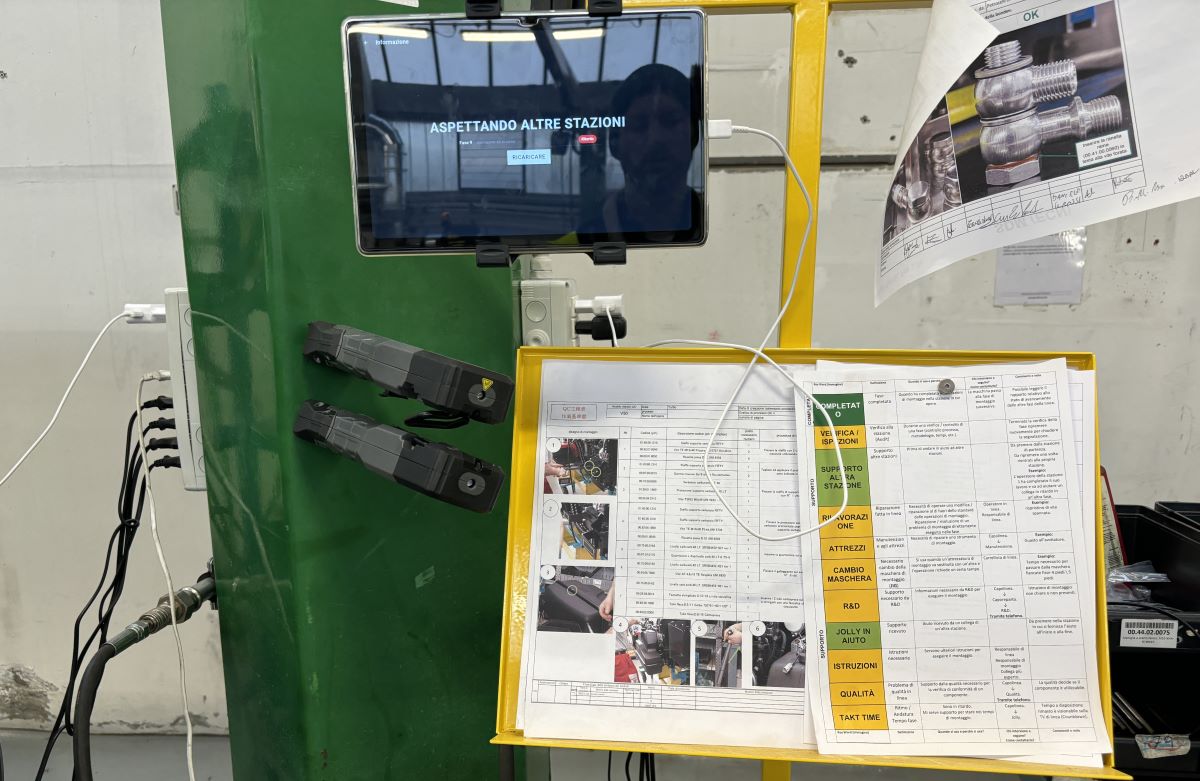

But everyone has their own approach to completing a task, which limits the consistency that can be achieved. To prevent this at the factory, beside each stage of the construction process is a standard operating procedure that is followed by each member of the team. It means that whether you’re doing a job for the first time or the thousandth, standards will be ensured.

By seeking multiple perspectives, you will gain an understanding of how your operations impact others, such as your fellow greenkeepers, other golf club staff and ultimately your customers. Each of these has a valuable role to play in the success of your business.

At Gianni Ferrari, magnetic pins prevent machinery components rattling during usage, a change suggested by a customer that improves things for other users. Other small changes can add up and have the potential to have a big impact in future.

At the factory, technicians previously had their tools and components hung on a wall or in drawers. Now, they identify what resources they will need throughout the day and load them onto a trolley, which they can move alongside them as they work. It removes the need to leave their workstation to gather equipment and parts, saving seconds that add up to minutes and so on.

How much time do you spend each day, heading between holes or back to the facility to pick up some tools you need? By considering these factors, small gains can soon add up to huge improvements.

Greenkeepers are adept at finding low-cost ways to improve their operations, they are renowned for it. But Kaizen offers some guidance with its ‘just in time’ strategy. Rather than stockpiling resources, such as sand and aggregates or various other tools, raw components arrive on site just at the moment they are needed. This, of course, requires an effective supply chain, but imagine resources such as topdressing arriving at the club on the morning of or the day before you intend to get them out on the course. It would remove the need for a storage facility and reduce the amount of product lost while it is sat around waiting to be used.

It’s possible to be overwhelmed by data, but measuring changes and the impact they are having is a good way to determine if improvements are actually being made. For example, if you choose to let the rough grow out in certain areas, is it possible to measure the average playing time of golfers on that hole? Are your actions slowing down or increasing scores or the time it takes to play a round?

Focusing on the customer and understanding their needs is at the core of everything and so often we forget that.

At every step, continuous, proactive improvement is key. Mistakes will undoubtedly occur but as they do, consider solutions and look around for ideas to prevent it from happening again.

Asking ‘why’ five times is another key Kaizen principle. Doing so, it is believed, will get you to the root cause of an issue, while also giving team members the opportunity to learn why something happens in the way it does.

Kaizen works at Kubota, where the company has expanded rapidly in the European market since it was introduced 50 years ago. Kubota and Gianni Ferrari merged in 2022 and began implementing Kaizen immediately, with two factories combined into one and the Italian team learning how to work in the new structure.

One longstanding staff member is Rossano Angeli. Spectacled, balding, sat at a workstation, you would be surprised to hear that in his youth he played central midfield alongside Carlo Ancelotti for Parma Calcio.

The two remain friends to this day and you can’t help but think Don Carlo, the five-time Champions League-winning coach, would look favourably upon the principles of marginal gains, continuous improvement and arriving at just the right time.

“Carlo has a mentality like a farmer,” said Rossano. “A very simple guy. Hard work, no superficiality, not a dreamer.”

Hard work, no nonsense, alongside Japanese principles of continuous improvement. How might greenkeepers adopt this mentality to improve their working lives? GI

Small changes, big differences

Look around your workplace and consider what small changes you could make to improve the efficiency and effectiveness of your team. Even better, empower your team and create an environment where everyone feels comfortable contributing ideas. That will add to their enjoyment at work as they begin to feel recognised and appreciated.

Author

BIGGA

The 10 Kaizen principles

- Let go of assumptions

- Be proactive about solving problems

- Don’t accept the status quo

- Let go of perfectionism and take an attitude of iterative, adaptive change

- Look for solutions as you find mistakes

- Create an environment in which everyone feels empowered to contribute

- Ask ‘why’ five times to get to the root cause

- Gather information and opinions from multiple people

- Use creativity to find low-cost, small improvements

- Never stop improving